DAICHIN WELDING ELECTRODE NO.DCR-61 SB

Charecteristics

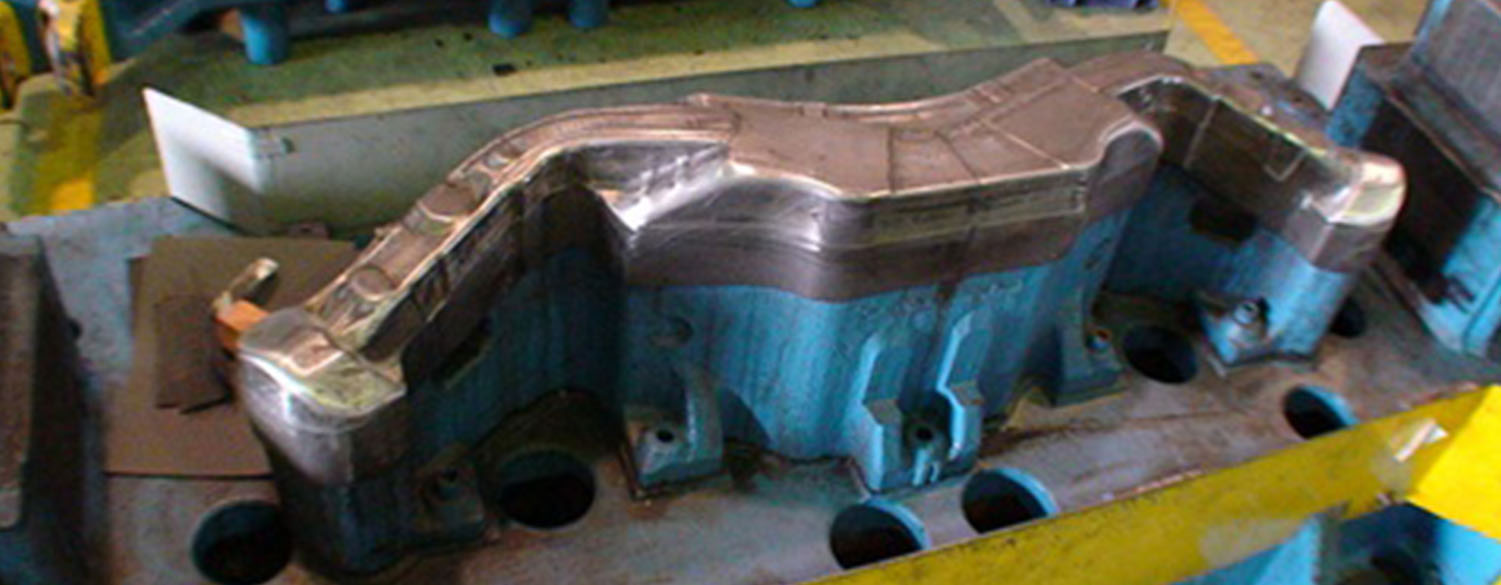

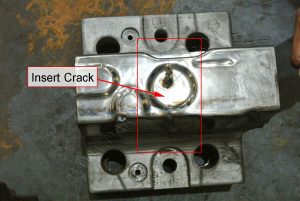

● R & D for using onto cold press mold such as SKD 11, SKD 61 (JIS), etc.

● Buildup and repair forging dies and punch unit.

● Especially for hard facing, cutting blades without preheat

and subject to TD, TiC coating such as Blanking Dies,

Gauge Cold Trimming Dies, Plastic Mold, Drawing Dies,

Punch, Slitter, Forming Dies, Thread Rolling Dies, etc.

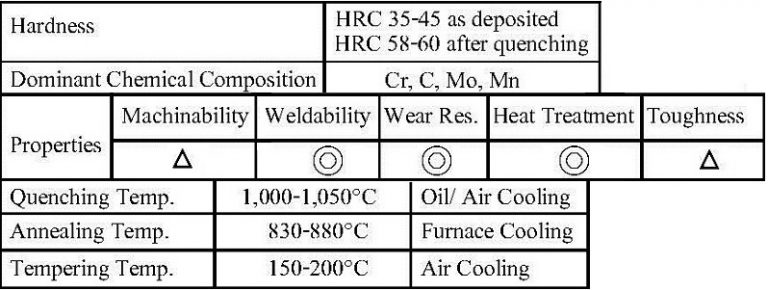

Mechanical Properties

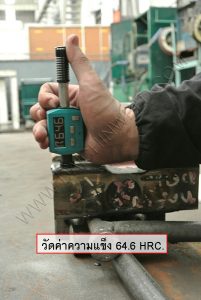

Hardness Range : 58 ~ 61 HRC

ลวดเชื่อมชุบแข็ง,ลวดเชื่อมแข็ง,ลวดเชื่อมพอกแข็ง ลวดเชื่อมชุบแข็ง TD~TIC เคลือบ

FOR COLD WORDING TOOLS AND DIES MADE OF SKD-11(JIS).

HIGH CARBON ALLOY FOR SEVERE ABRASIVE WEAR AND MILD IMPACT APPLICATIONS.

RESPONDS TO POST-WELD TREATMENTS.

Designed for cold working dies, such as SKD11(JIS).

Recommended for overlaying and builiding up edges where postweld heat treatment is required. typical applications are blanking dies. gauges.cold trimmer dies, plastic molds, drawing dies, punces, forming dies, and thread rolling dies.

As hardness as deposits is HRC35-45, deposit is machinable. Hardness will increase to HRC58-60 by heat treatment. Response to typical SKD-11 heat treatment alloy with excellent color match.

Base metal should be free of all, grease, oil, oxide or other contaminnation. Remove fatigued or damaged metal. Preheat 650-700 C° recommended for high crack sensitivity and /or quenched materials, plastic molds, and multi – layer welding. Peening is recommbended after every pass for relievibg residual stress. Postheat 700 C°. is recommended in case work is difficult condition to preheat, use TigTectic T-6055 for cushion layer. Quenching temperature is 1,050 C° and air cooling.